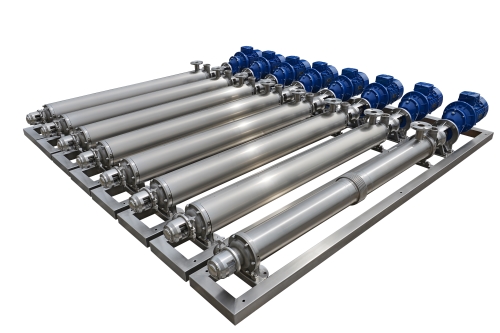

MBS SCRAPPED SURFACE TUBULAR HEAT EXCHANGER-MADE IN ITALY

MBS S.r.l.

How it works

l) The product enters and leaves the heat exchanger through specially profiled cylinder heads, which are designed for easy product flow and low stress; especially good for the safe processing of shear sensitive fluids.

2) Blades attached to the rotating shaft, create a gentle and high~ effective recirculation action as the product passes through the heat exchange cylinder; this ensures that an even temperature is achieved throughout the fluid.

3) IThe service media, which normally flows “counter current” through the cylinder shell, can provide efficient heating or cooling over a wide range of medium to high viscosity products.

Advantages

– Reliable Heat Transfer with Challenging Products

– High Thermal Efficiency with Gentle Handling

– Easy Disassembly and Inspection.

– Low Maintenance requirements.

Application range

Ideal for viscous and delicate products, particularly for those containing soft solids. Perfect for complex fluids which tend to ‘bum-on’, coat or solidify on hot or cold surfaces.

Products

Fruit pie filling, jams & preserves, ketchup. mayonnaise, chocolate, sauces, soups, ready meals, ragù, gelatin, baby food. honey. sugar. confectionery. butter. cheese curd, ice cream, oils, fats, emulsions, liquid egg etc.

MA JINNAH TRADING is working closely with MBS (CSF GROUP) for supply of Hygienic Process Equipment's

Covering GCC & Pakistan

We supply original OEM Equipment's & Spares.

About MBS

In 2008 MBS became part of the CSF Inox Group. MBS is now a leading supplier of heat exchangers in Italy and around the world and is ISO 9001 certified.

The MBS team of experts can provide total technical and commercial support in the heat treatment of foods, chemicals and pharmaceuticals. Application of the ‘lean production’ method, use of top quality raw materials and special materials together with years of experience and professionalism in this specific sector, guarantee a high level of quality on the whole catalogue of products.